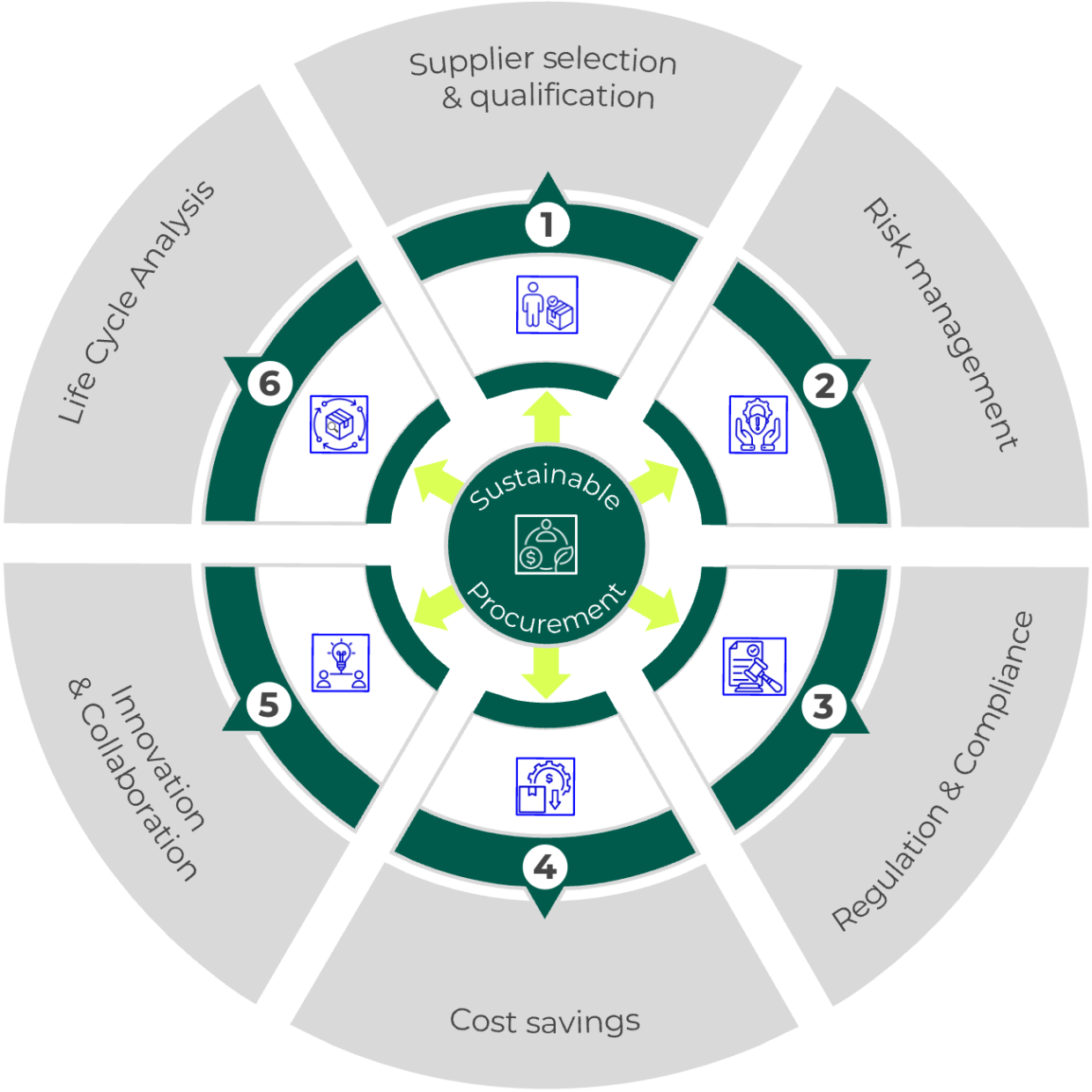

Procurement has shifted from a pure focus on supply, cost, and efficiency to a broader consideration of environmental, social, and ethical factors. This shift is based on the recognition that sustainable procurement not only aligns with global goals for a more responsible and equitable world but also makes good business sense.

Below are some specific examples of how procurement is directly driving the implementation of sustainability:

1 / Supplier Selection and Qualification

Companies are increasingly considering the sustainability performance of potential and existing suppliers when making procurement decisions. A holistic sustainability performance of the entire supplier base is often queried and evaluated with the help of rating agencies. Suppliers are assessed based on their environmental, social, and governance (ESG) practices and are required to provide relevant evidence and certifications independently and proactively. Suppliers not meeting a minimum set of requirements are no longer competitive and may be excluded from tenders. Investing in supplier sustainability is therefore worthwhile in terms of competitiveness alone!

2 / Risk Management

While risk management in the supply chain is often multi-faceted (e.g., operational risks, supply security, geographic, and natural risks, political risks, as well as financial and cyber risks), sustainability in the environmental and social sense is an increasingly relevant risk. Procurement teams are assessing the sustainability risks associated with suppliers, such as compliance with human rights, environmental protection, scarcity of resources, and reputational risks, and initiating appropriate prevention and mitigation measures with suppliers. This is already lawfully required in several countries (Australia, Germany, France, the UK, the Netherlands, Norway, Switzerland, and the USA).

3 / Adherence to Regulatory Requirements & Compliance

Increasingly stringent environmental regulations and global sustainability standards are impacting procurement decisions. This is because the requirements must be translated into implementation within the supply chain. Companies need to ensure that their suppliers comply with the relevant laws and regulations on environmental and social practices and enforce them in the indirect supply chain. Transparency and data availability requirements are becoming more stringent. In the event of environmental or human rights violations in the supply chain, both the suppliers themselves and the purchasing companies face heavy fines.

4 / Cost savings

There is still a common assumption that sustainable procurement practices compete with cost-cutting initiatives. However, this does not necessarily have to be the case; in fact, they can complement each other perfectly. In the long run, sustainable procurement practices can lead to significant cost savings. Energy-efficient products and services, waste reduction, and resource optimization are just a few examples that can contribute to lower operating costs and greater operational efficiency. The procurement sector has been tempted by the initial expenditure not to implement the necessary measures. Legislators have therefore responded with the Supply Chain Duty of Care Act. It is now time to take a more long-term “sustainable” perspective. Procurement measures are the core elements of a company’s sustainability strategy. The example of climate protection shows that CO2 emissions in the supply chain account for a large proportion of a company’s emissions.

5 / Innovation & Collaboration

Procurement is no longer just about cost savings, but also about fostering innovation and collaboration with suppliers. Incentives for sustainable procurement encourage companies to work closely with suppliers to develop and implement innovative, environmentally friendly solutions. In this way, new frameworks can be jointly created, and current challenges can be tackled collaboratively.

6 / Life Cycle Analysis

A life cycle assessment (LCA) helps companies understand a product’s or service’s environmental impact throughout its entire life cycle – from raw material extraction to disposal. By conducting an LCA of purchased products and services, companies can identify opportunities to actively reduce environmental impacts and make more sustainable decisions. The basis for this analysis is product and logistics data, which can only be collected in cooperation with suppliers. Once again, the role of the procurement organization and supplier management is essential.

“The fact that sustainability must integrate into all areas of strategic purchasing in order to ensure future economic success has been widely understood. But the extent to which these areas are influenced is only now becoming much more transparent!”

Get in touch!

P3 can support you in transforming your procurement organization towards sustainability from an operational and strategic perspective, e.g., in:

- Formulating your sustainable procurement strategy based on your overall business objectives

- Developing an appropriate organizational collaboration model, corresponding departments, and processes

- Training and empowering your procurement professionals in the area of sustainability

- Empower your teams with the appropriate toolkits for smooth operational activities in dealing with suppliers

- Ensure long-term compliance with sustainable procurement and supply chain regulations

- Collaborate with your suppliers and implement initiatives and development programs to achieve your common goals

- Implementing new processes due to new requirements, such as obtaining the necessary emissions data from suppliers outside Europe due to the EU’s Border Adjustment Mechanism (CBAM). We provide process knowledge and capacity so that the procurement organization does not have to neglect its core tasks.

If you have any further questions about sustainable procurement at P3 or would like information about our services, please do not hesitate to contact us.